Sensors

When you need the capabilities of a Coriolis mass flow meter, the Rotamass TI has been specially designed to maximize your asset performance and return on investment.

When every drop counts

The world's smallest dual bent tube Coriolis flow meter series for highly accurate measurement at lowest flows.

The dual tube design compensates for fluctuations of density, temperature, pressure and environment conditions. This provides a consistent repeatable and accurate measurement especially for small size Coriolis flow meters.

Typical Applications

- Batching

- Dosing

- Blending

- Chemical injection

- Dosing systems

- High pressure gases

- Liquid and gas low flow measurement

- Precision coatings

- Metering pump control

- Metrology

- R&D laboratory

- Vacuum thin film coating

Versatile in applications

The versatile Coriolis flow meter with superior turndown and lowest pressure drop in the market.

Ideal for a broad range of standard applications, this series is a flexible and cost effective solution for highly accurate flow and density measurements. Features, such as concentration measurement or the tube health check function allow the meter to be adjusted to customer needs.

Typical Applications

- Batching

- Blending

- Chemical recovery

- Continuous reaction

- In-line concentration and density measurement

- Catalyst feed

- Filling and dosing

- Mass balance

- Net oil computing

- Palm oil

- Process control

Experience meets innovation

The Coriolis flow meter with superior performance under demanding conditions.

The successful Rotamass series has been progressively developed and is also newly equipped with the latest technology. This meter delivers unsurpassed performance for demanding and critical applications with superior aeration handling and advanced diagnostic functionality.

Typical Applications

- Batching

- Burner control

- Feed and product control

- Filling and dosing

- Gas void fraction

- In-line concentration and density

- Loss control

- Material and mass balance

- Net oil computing

- Process control

- Solvents

- Water cut

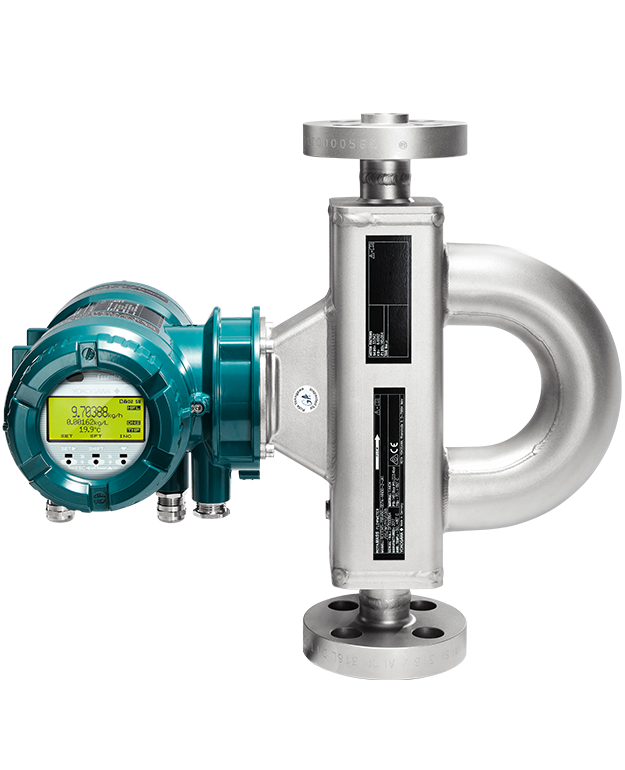

Safe under high pressure

The Coriolis meter with the most robust and durable design for precise measurement in high pressure applications.

Safety is always a concern and especially when operating at high pressures. Therefore, this series has been designed to meet the highest safety requirements. Combined with advanced diagnosis such as the “Total Health Check” function, operation is always under secure control.

Typical Applications

- Chemical injection

- Compressed gases

- Fuels

- Glycol TEG/MEG

- High pressure gases

- Hydraulic oil

- Hydrocarbons

- Liquified gases

- Natural gas hydration

- Offshore and onshore

- Oil refinery processes

- Solvents

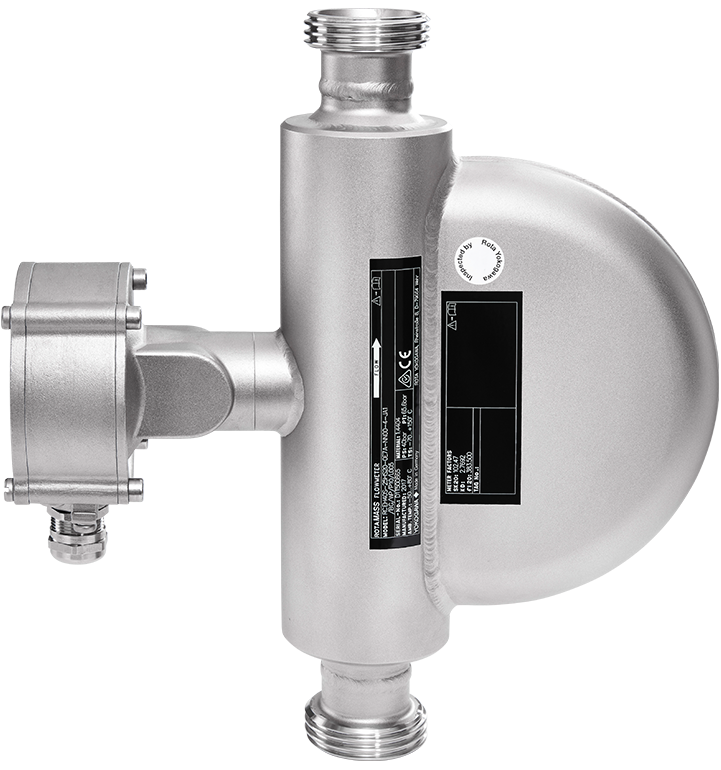

With pure dedication

Specifically designed and certified for food & beverage, biotechnology and pharmaceutical utility applications.

This series is the appropriate answer to the daily constraints of hygienic processes ensuring continuous product quality and minimizing losses. This is made easy by the provided multi-variable measurement and various dedicated features.

Typical Applications

- Bioreactor feeds

- Bottling

- Carbonation of beverages

- Deionized water

- Fermentation

- Juice processing

- Molasses measurement

- Online sugar concentration

- Raw milk tanker unloading

- Process water reclamation

- Product quality control

- Sugar industry

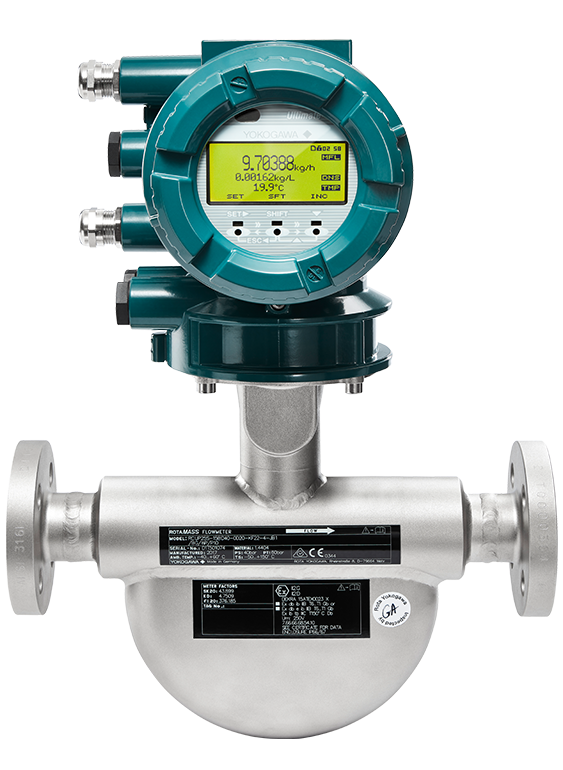

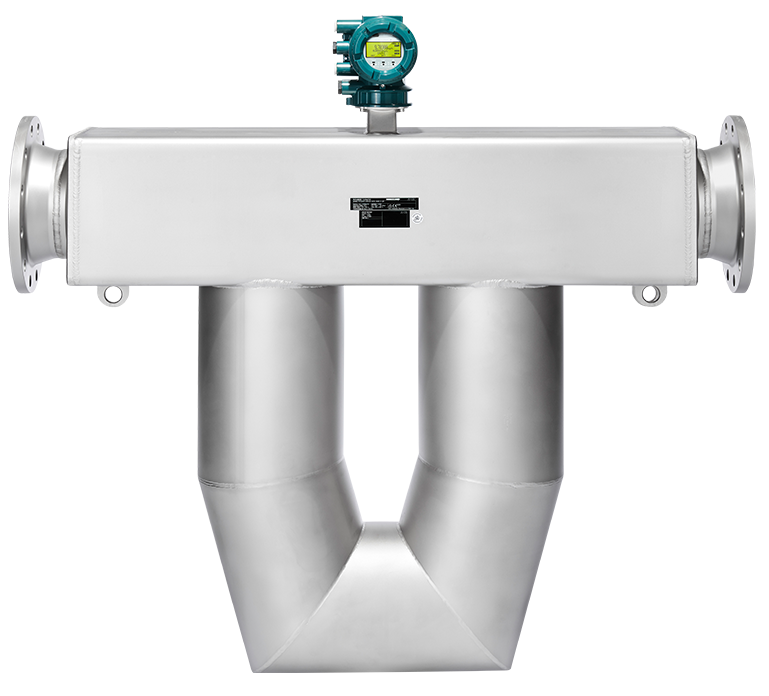

Big in performance

Delivering best in class accuracy and most flexible installation at high flow rates.

The unmatched accuracy at the low end of the measuring range offers maximum flexibility from engineering to final operation. This series unifies a long service life with low maintenance costs and reliable performance.

Typical Applications

- Bitumen

- Distribution networks

- Drilling mud

- LNG

- Rail car loading

- Ship loading

- Truck loading

- Tar

- Offshore and onshore

- Oil well cementing and hydrofracturing